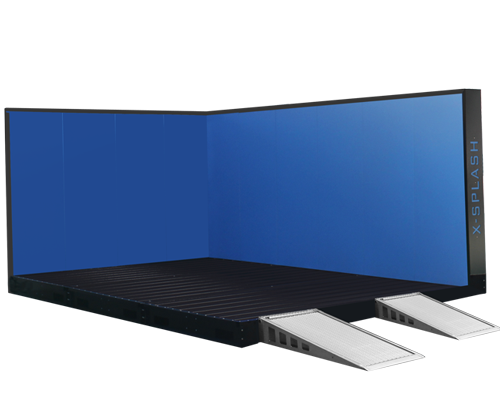

X-3

A self-contained, environmentally friendly, cleaning system for construction plant and equipment.

Download Datasheet

HOW IT WORKS?

The wash bay is made with a diamond tread ramp and a 87″ high wall. The wash bay floor pan directs the dirty water and sludge from the equipment being cleaned to a solids collection tank at the rear of the wash bay. Inside the rear tank, a float switch activates a diaphragm pump which delivers the dirty water into the filtration tanks to start the filtration process. After the water has been through this process, a booster pump delivers the water again to your pressure washer. Through the filtrating system, you can use the same water repeatedly. The filters inside the separator tank can be easily replaced, guaranteeing an adequate filtering barrier.

![]()

![]()

![]()

![]()

Advantages

- The system allows you to recycle water and prevents the contaminated water from going into the drainage system;

- Less water used means more money is saved, and more savings made with handling and washing time;

- Easily transportable, easy to assemble and disassemble;

- Innovative design and the modular construction system make our wash bays suitable for several indoor and outdoor uses;

- Environmentally friendly.

Technical data

| Technical Specifications X-3 | |

| Useful dimensions | 118″ x 177″ |

| Total dimensions | 141″ x 226″ |

| Filtration tank dimensions (X-10) | 111″l x 29″w x 40″h |

| Maximum load capacity | 11,023 lbs |

| Walls standard heigh | 87″ |

| Total dry weight of the bay | 3,792 lbs |

| Diaphragm pump | 0.054kW – 4.5 gpm |

| Booster pump | 0.37 kW – 1.3 to 11 gpm |

| Filtering system | X-10 |

| Option filtering system | X-30; X-60 |

| Option maximum load capacity | 22,046/44,092 lbs |